-

PCD PCBN Inserts

PCD Advanced Material

The hardness of Polycrystalline Diamond material is second only to natural diamond in nature. Diamond layer is excellent mechanical sup-ported because PCD layer be closely integrated with the based carbide. It has widely used in the cutting tool for machining non-ferrous metals, non-metals and difficult to machine materials because of its excellent per-formance. Improve the production efficiency for customers. -

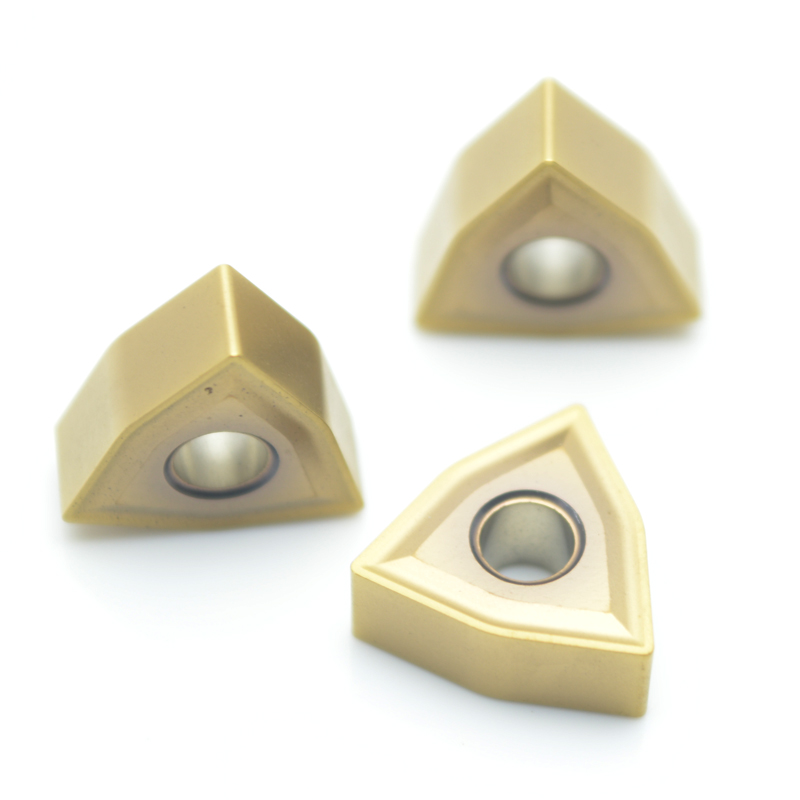

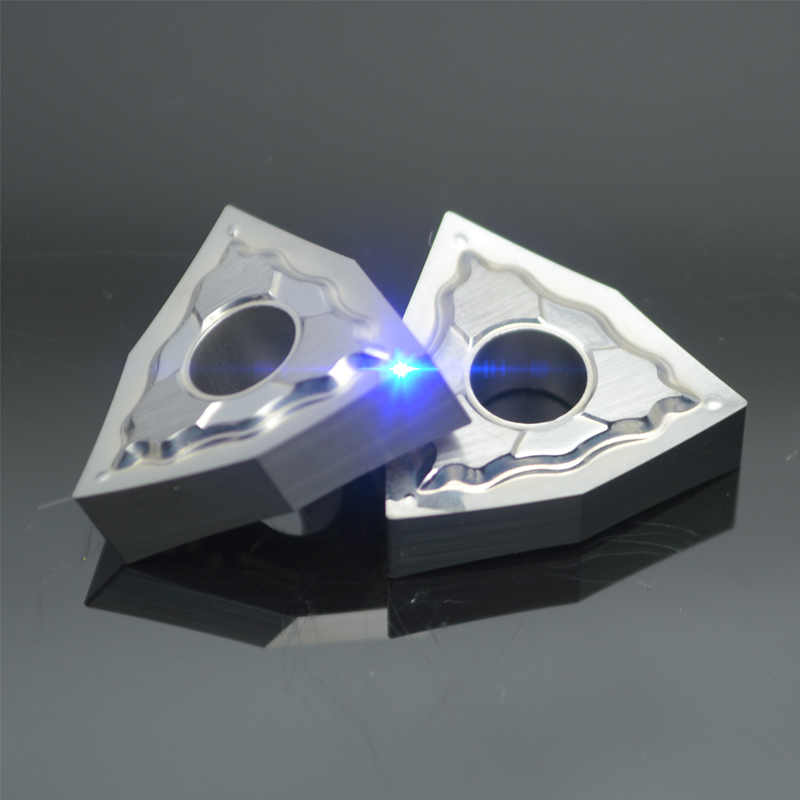

CVD Coated Carbide Inserts

EDGEV CVD (chemical vapor deposition method) is mixed a vari-ety of gas into a high temperature reaction tank, so that the surface of the based material to be manufactured the super hard particulate matter. From the gaseous state, without passing through liquid, to direct transi-tion VS growth mode as a solid state, to form a film of several microns to several ten microns. Compared with the single-layer PVD coating, its hardness, wear resistance and red hardness even more remarkable ... -

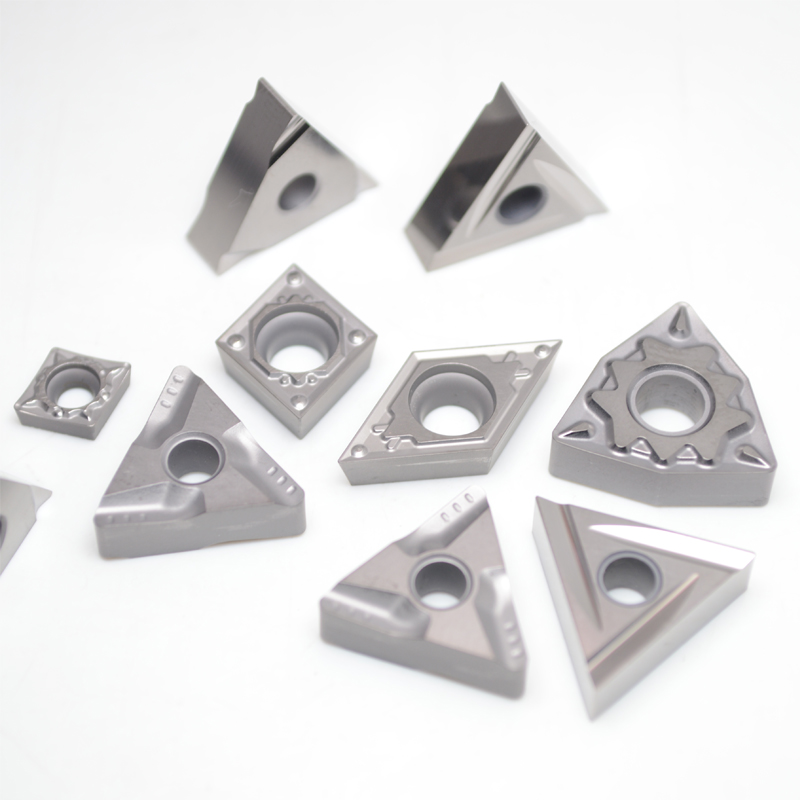

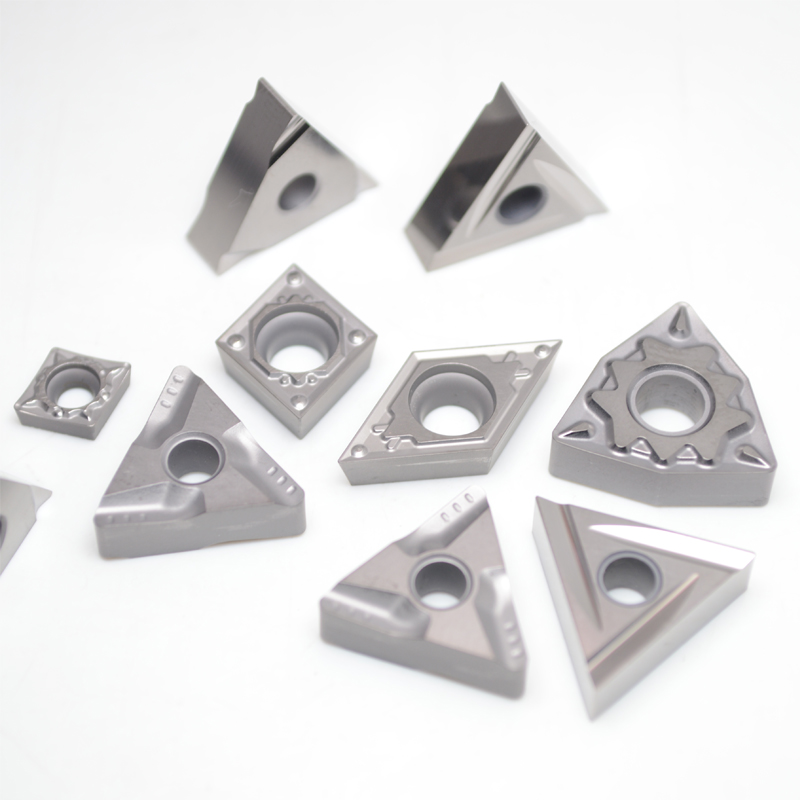

Cermet Inserts

Cermet Grade Introduction

Ti(C,N) cermet is a new and potential material which not only has toughness, high thermal conductivity and good heat stability of materials, but also has high hardness, high red hardness and corrosion resistance of ceramics. The unique physical and chemical properties of cermet make if promising in special cutting tools, wear parts and corrosion-resistance parts. -

Uncoated Carbide Grade Introduction

As the leading cutting tools, Cemented carbide tools in the CNC industries are widely used for a long time because of its superior me-chanical properties and low machining cost, until now, we can differently provide all kinds of cemented carbide products,

ETi10 and ETi20 which are used for machining of steel (Hardness is less than HRC45),

EK10 and EK30U which are used for machining of cast iron and non-ferrous metals. -

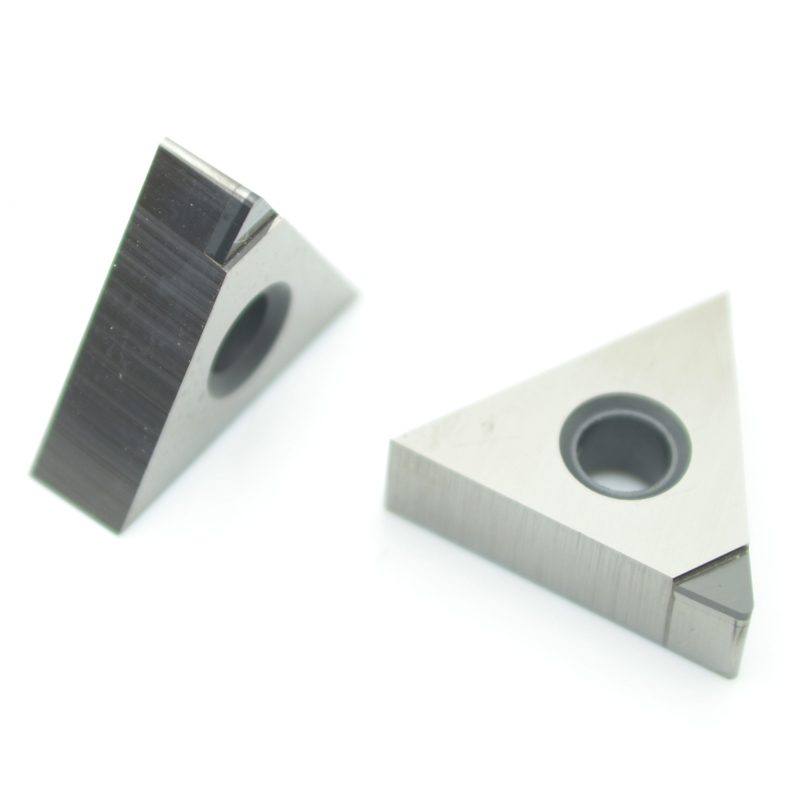

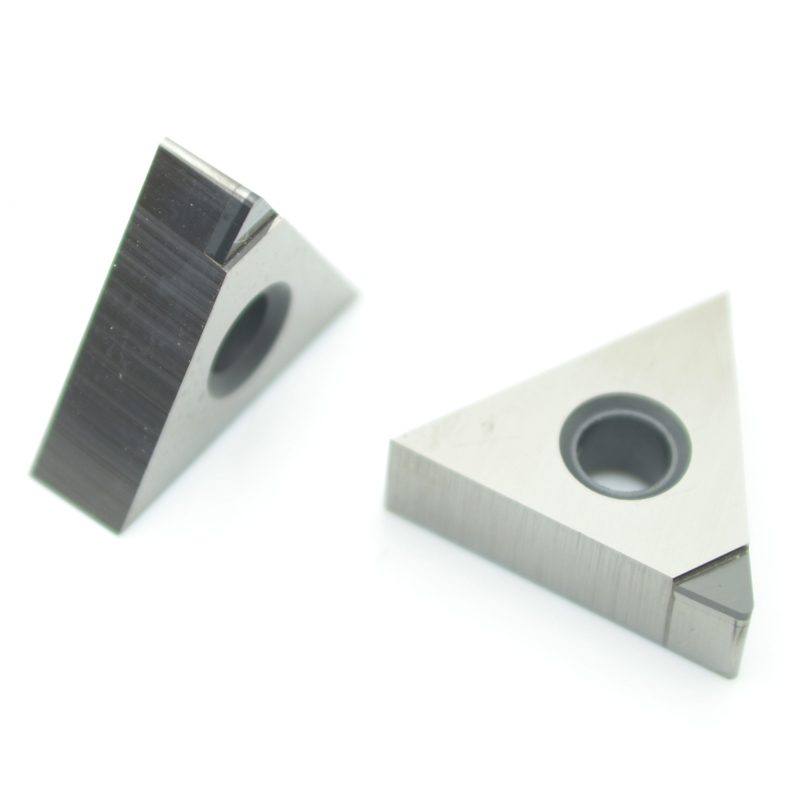

Solid CBN Advanced Material

Hardness and thermal conductivity of our Cbn and Pcbn is second only to diamond crystals, it is sintered under high pressure and high tem-perature. -

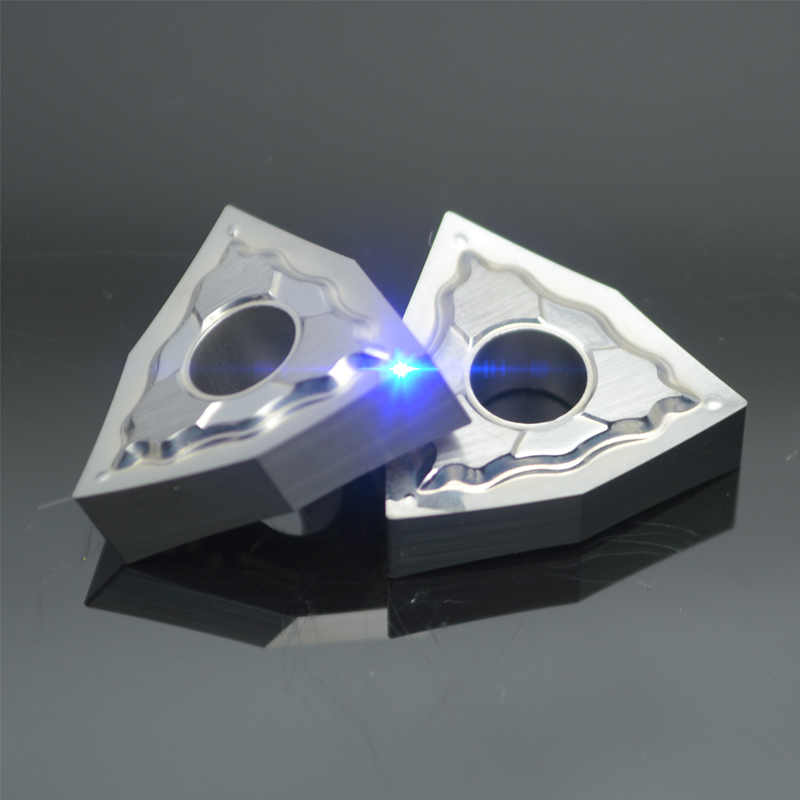

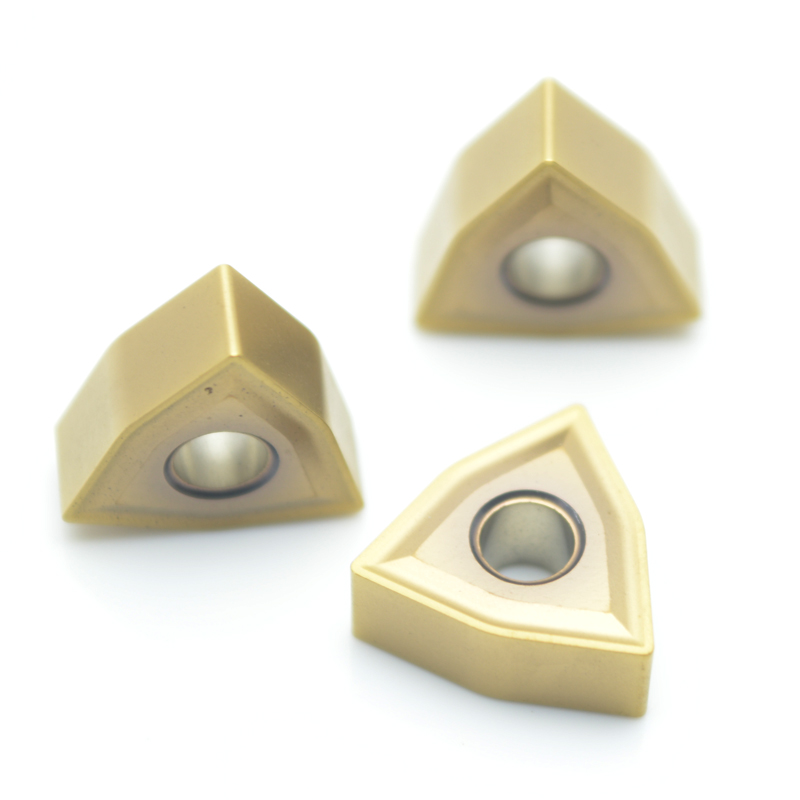

PVD Coated Carbide Grade Introduction

EDGEV PVD (Physical Vapor Deposition) coatings are manu-factured through using an arc evaporation processing, high evapo-ration on the surface of cemented carbide, and to be combined with the reaction gas in the controllable state, and deposited into a variety of different wear resistance film, all of coatings are used the composite single layer and multilayer nanostructures. Compared with the CVD film, the film is more uniform, to ensure a long life of cutting tools.